WES, WCS, WMS: Which System Does What?

When it comes to choosing warehouse software for your order fulfillment operation, it can sometimes feel a bit like wading through a vat of alphabet noodle soup. Acronyms and abbreviations abound, making it tricky to parse the differences between the different programs that you are considering.

One example that can sometimes cause confusion is the relationship between a WMS, WES, and WCS. But though only a single letter separates each of these softwares, the actual differences between what each does cannot be overstated. Simply put, each performs a unique role within an order fulfillment operation, and it’s important to understand what those roles are.

Below, we take a look at each of these different types of warehouse software and explore specifically what each is responsible for in your business.

WMS vs. WCS vs. WES

What does the WMS do?

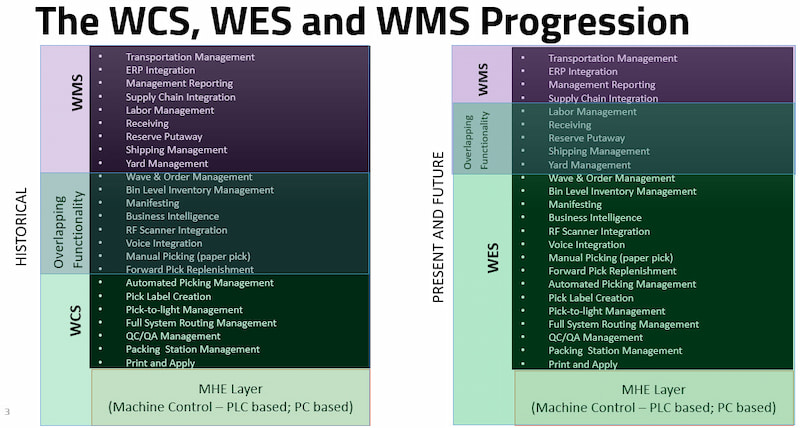

The warehouse management system (WMS) is primarily responsible for the flow of inventory within your facility, from receipt of product to putaway, replenishment, and shipping. This means that the WMS has historically performed the following functions:

- Transportation management

- ERP integration

- Management reporting

- Supply chain integration

- Labor management

- Receiving

- Reserve putaway

- Shipping management

- Yard management

Depending on the operation, the WMS may also be responsible for these additional functions:

- Wave and order management

- Bin level inventory management

- Manifesting

- Business intelligence

- RF scanner integration

- Voice integration

- Manual picking (paper slip)

- Forward pick replenishment

What does the WCS do?

The warehouse control system (WCS) integrates with the WMS in order to provide an additional layer of controls and functionality. It is specifically designed to control any automated technology or equipment within a facility, such as conveyors, sorters, AS/RS, etc.

With this in mind, the WCS has historically been responsible for the following functions:

- Automated picking management

- Pick label creation

- Pick-to-light management

- Full system routing management

- QC/QA management

- Packing station management

- Print and Apply

Because the WMS and WCS overlap in functionality, the WCS can also perform these functions that may be performed by the WMS, depending on the needs of the operation and the specific capabilities of each system:

- Wave and order management

- Bin level inventory management

- Manifesting

- Business intelligence

- RF scanner integration

- Voice integration

- Manual picking (paper slip)

- Forward pick replenishment

What does the WES do?

Finally, the warehouse execution system (WES) can be thought of as the next generation of the WCS. In this regard, it provides the same functionality as the WCS, but builds upon it in order to offer a higher level of warehouse management:

- Wave and order management

- Bin level inventory management

- Manifesting

- Business intelligence

- RF scanner integration

- Voice integration

- Manual picking (paper slip)

- Forward pick replenishment

- Automated picking management

- Pick label creation

- Pick-to-light management

- Full system routing management

- QC/QA management

- Packing station management

- Print and Apply

As with the WCS, the functionality of the WES can overlap with that of the WMS, including:

- Labor management

- Receiving

- Reserve putaway

- Shipping management

- Yard management

WMS & WES: A Partnership Built for Success

What’s important to note about the relationship between the warehouse management system and the warehouse execution system is that it is not an either/or discussion. Your operation almost certainly needs a WMS to be successful. A WES will not replace your WMS—but it can play an important role in supporting and augmenting your WMS.

It does this primarily by performing functions that the WMS is not capable of doing or doesn’t do well on its own: Wave building, order processing, picking management, and individual equipment, among others. Without a WES, the only way to introduce this functionality would be to invest in the costly and time-consuming task of custom development, which can also bring risk of software failure with it.

WES vs. WCS

The relationship between the warehouse execution system and the warehouse control system is exactly the opposite. While the WES is meant to complement the WMS, it is meant to replace the WCS. This is because the WES simply does the job of the WCS better.

A WES includes not only the individual machine controls capabilities of the WCS, but more. Labor management and order management capabilities are among the most impactful. These, paired with the automation management, allow for a more holistic approach to warehouse management and, ultimately, a more efficient system.

When a WES Makes Sense

There are a number of scenarios when implementing a WES can make sense for an operation.

The first is, as mentioned above, if you have a legacy WMS and a wishlist of functionality that you want to add. Instead of investing in custom code and potentially introducing risk to your WMS, you can find a WES that adds in that functionality in a safer, more cost-effective, and more efficient way.

The second is if you have a WCS and have hit the wall on efficiency. For example, if you are having issues due to the fact that your different zones are not synchronized, or if you are not getting the best performance out of your equipment, or if you would like to introduce new equipment into the facility. Likewise, the WES can often optimize your labor resources. Replacing your existing WCS with a WES can help you resolve all of these challenges.

A trusted systems integrator and software provider can help you understand your options and guide you to the solution that makes the most sense for your business. Contact us today to speak with a member of the Conveyco Team.